Line tracking is used in robotic pick and place applications. Products are being picked off of a moving belt, conveyor, etc, and placed to another moving or stationery area.

Line tracking uses the conveyor encoder direct sending data to robot’s controller and in combination with machine vision is used in a growing number of manufacturing applications – sometimes for a variety of reasons.

Line tracking with 2D or 3D vision control can help to locate, track, and inspect products and processes.

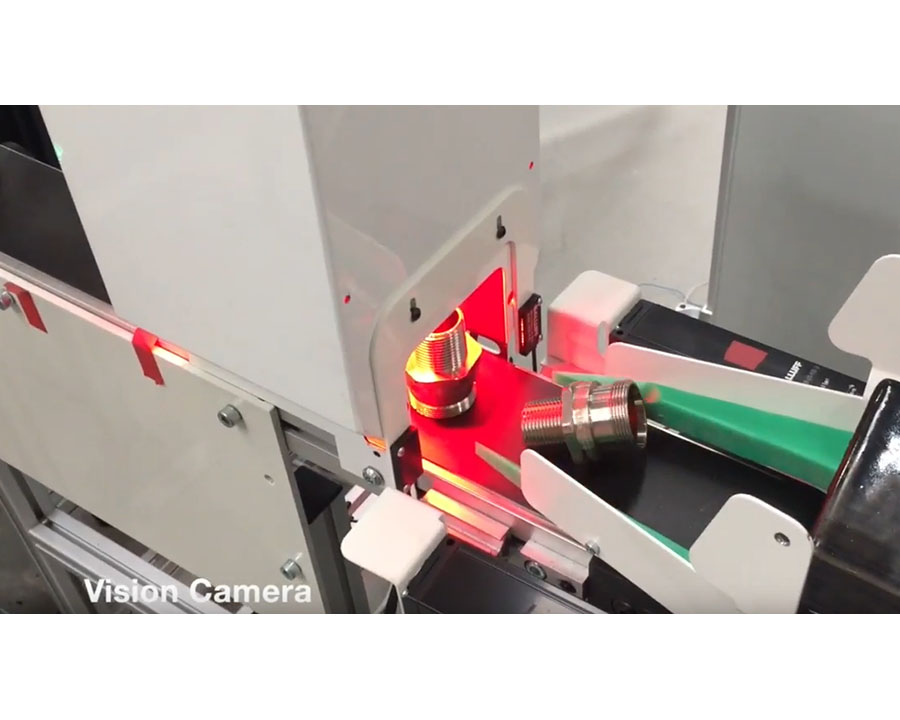

How does vision line tracking work? Example with one of our case study…

Mechanical feeding system, which is delivering product in large quantities onto a belt conveyor, where they are randomly presented to a handling robot. A plc fully controls the process and all product variants are introduced into the system from a bulk hopper. A vision system is used to identify all 80 different shapes and to determine the product type, position and orientation, as they travel along the conveyor. The robot is then able to orientate automatically, pick the parts from the conveyor and place them to the laser marking index table.