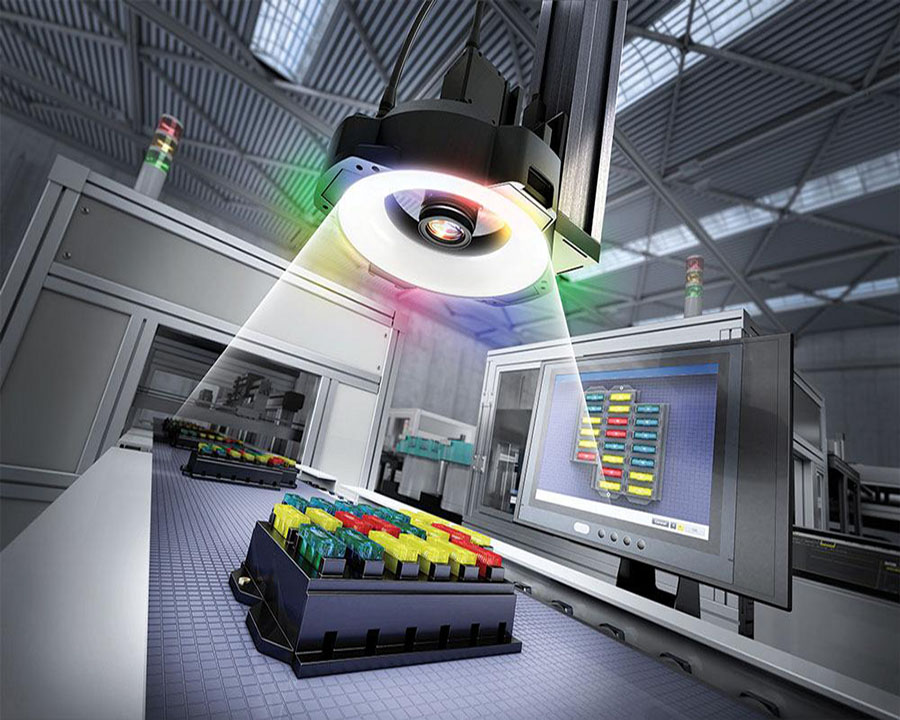

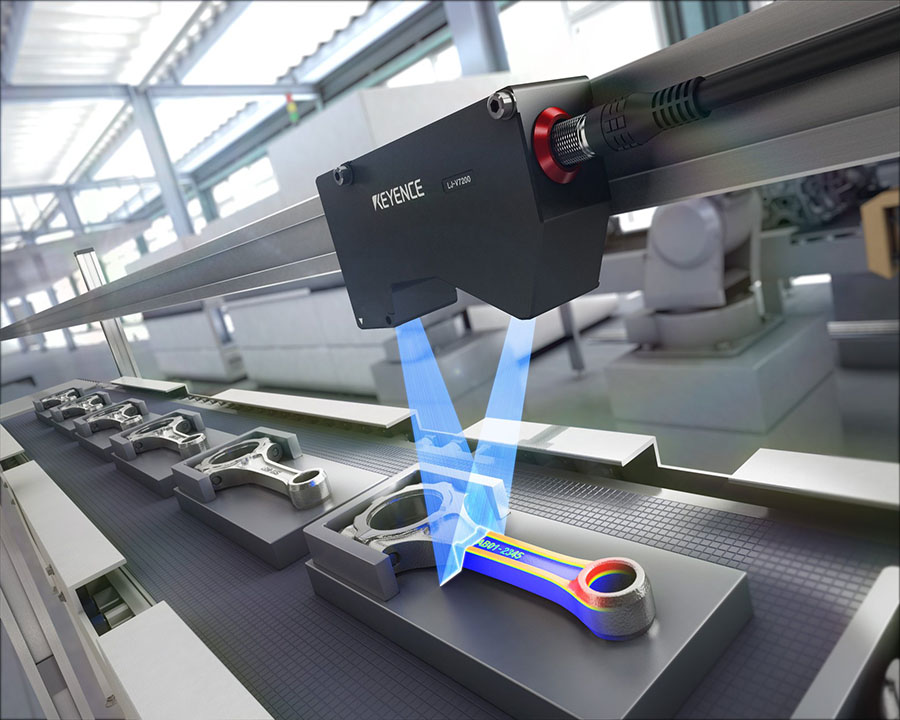

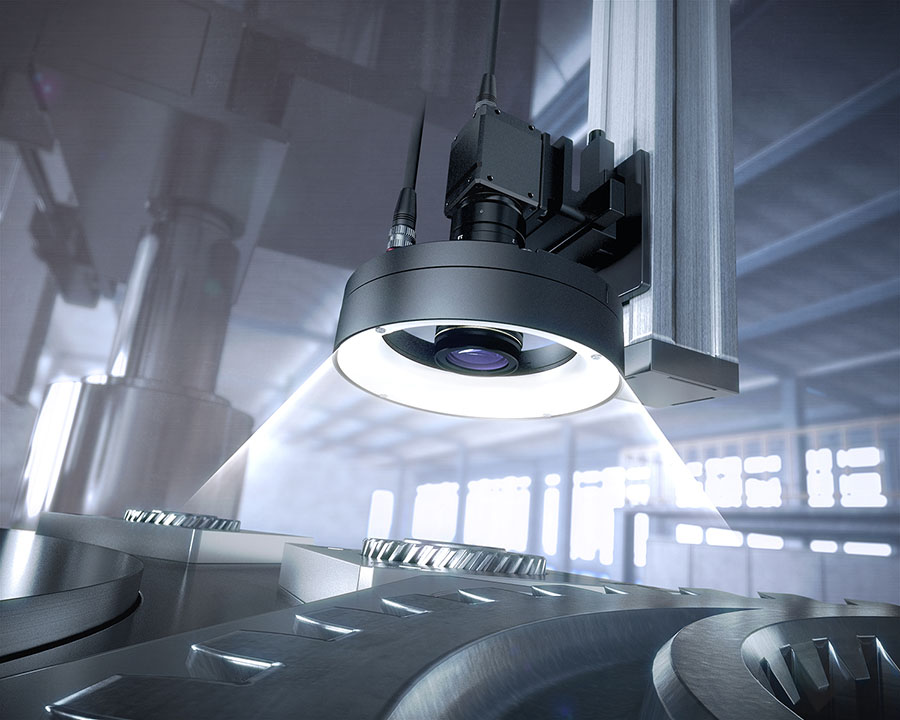

Through specialized algorithms and software development, we use state-of-the-art vision equipment to drive systems to their full potential.

Embracing the uniqueness of your business process needs, highly experienced engineers are dedicated to providing the best solution for your applications.

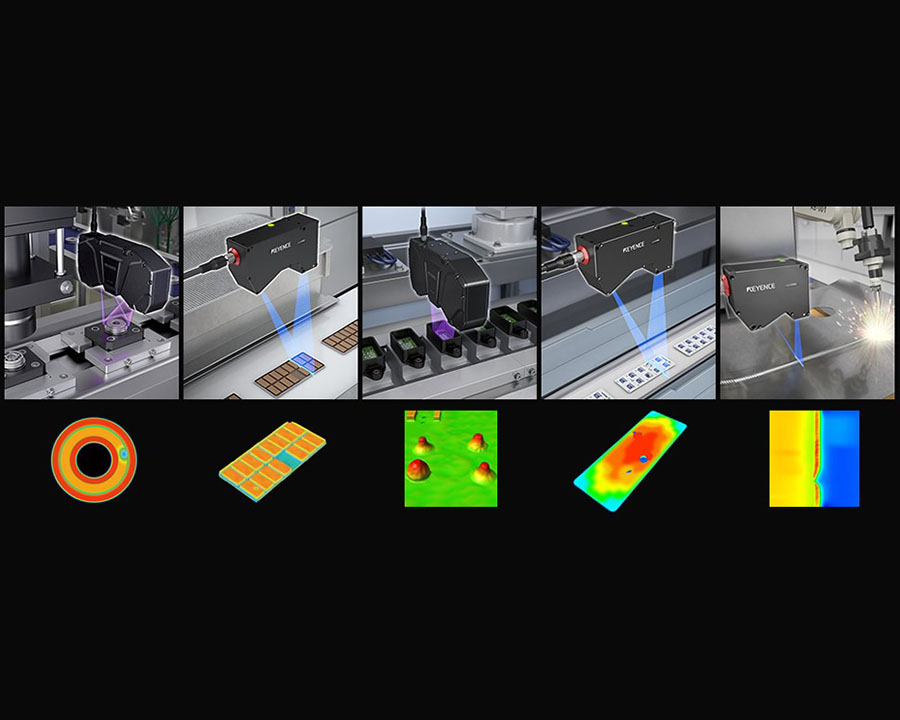

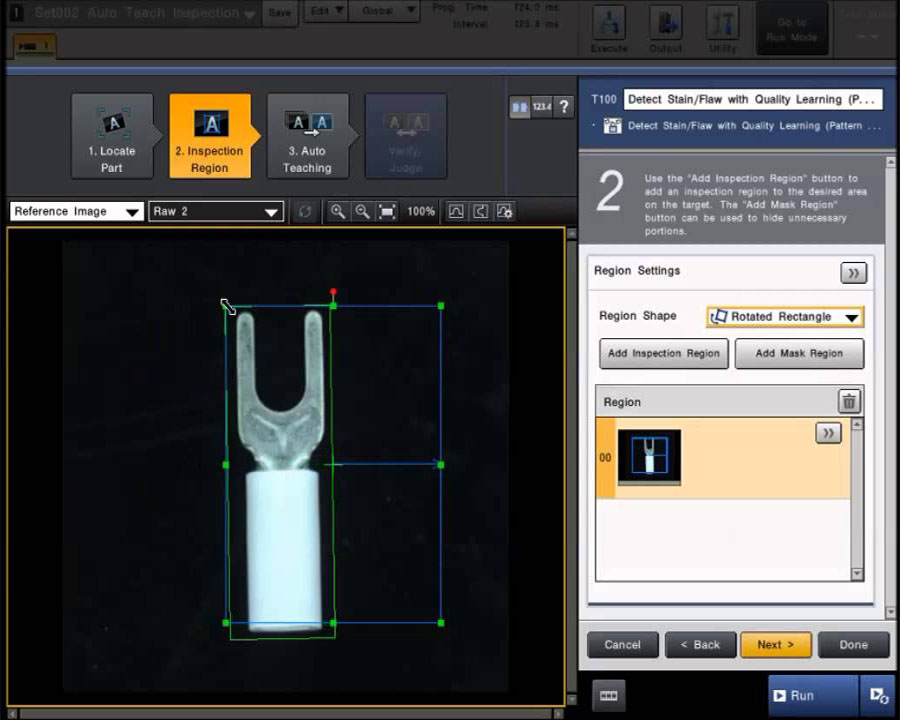

Whether the vision systems are used for quality inspection, process validation or high accuracy measurements, you can be sure the system has been fully designed to deliver the final product according to the specs with zero fault.